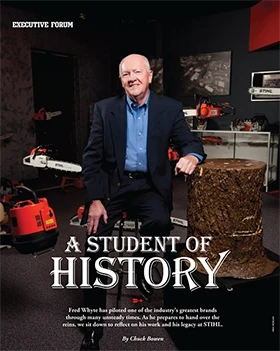

Long before he was the president of the U.S operation for the number one selling brand of chainsaws in the world , Fred Whyte was a twenty-something newlywed with a communications degree and a job with Datsun.

Long before he was the president of the U.S operation for the number one selling brand of chainsaws in the world , Fred Whyte was a twenty-something newlywed with a communications degree and a job with Datsun.

After getting his masters degree at the University of Iowa, Whyte had plans to move to Datsun’s offices in Chicago with his wife, Karen.

Then, he got a call.

His father, who then was regional manager for importer, STIHL American, told him the central states regional manager position was opening up for the German-owned chainsaw company.

Though he had spent a few summers working for Homelite in Seattle, working in the power equipment industry was never really in his long-term plans. “I had no intention of going to work for Stihl,” Whyte says.

Whyte, a Vancouver, Canada native, would move up the ranks at STIHL in the U.S. and then lead STIHL’s expansion and operations in Canada. In 1991, Whyte got another call. He was asked to take over as president of STIHL

Whyte has seen the company grow into a massive employer and driver of innovation in the hand-held segment. He’s helped steer it through recessions, and avoided the siren’s song of big box stores, instead continuing to rely on independent dealers and distributors.

“History is a great teacher,” Whyte says. “I think, in a lot of ways, that you try not to replicate the sins of the past, and I think it’s applicable to business as well.”

When he retires at the end of 2013, Whyte will have logged more than four decades with STIHL. This summer, we sat down with him in his Virginia Beach office to learn more about his tenure, what the future holds and what it was like to be his dad’s boss.

So your father, when you joined the company, was also working for STIHL American. He covered everything west of my territory. So between the two of us, we essentially had everything west of the Mississippi River.

How did he react to your eventual rise up to this position? My father was one of my greatest supporters, and I always told him it was poetic justice that I became his boss when I was 34 years old, because I could get back at him for all those times he never paid me for mowing the lawn. But my father did not have a jealous bone in his body. He shared everything with me. He really gave me a lot of insight into the industry and was a real mentor for me.

Can you give me an example? One thing that really stuck with me for many, many years was he said, ‘You will go into a dealership and they will ask you a question. They already know the answer to that question but they’re going to find out whether you’re full of BS or not.

So if you don’t know the answer, you better say you don’t know the answer but then promise to get back to them with an answer.’ And that actually happened on a few occasions.

Walk me through a typical day for you here in your current role. I come in early and that serves people very well here – come in early and stay late. People put in a lot of time, a lot of weekends, do a lot of travel. I try and get in and look at my email early because Germany is six hours ahead of us, so I can see the correspondence that has come in essentially overnight, handle some things quickly with a response or determine if that entails a phone call back here.

I try to avoid this whole meeting scenario that people can get caught up in. I used to have a sign in here that was very impolite. “None of us is as dumb as all of us.”

I think you have to be careful about tying up too much time in meetings, but face-to-face communication is obviously very important. You have to be careful because email can become a disease, and when you learn people are sitting in the next office sending each other email you want to say, “Get off your butt and go over there and talk to your colleagues.” It’s a balancing act to make the most effective use of time and technology.

I also still spend a lot of time traveling. I’m gone between 65-70 nights a year, and I make it a point to travel with territory managers and actually go out and see dealers. Because you can read reports and you can talk to your product managers, but I’m kind of a tactile person. I like to touch it, feel it, see it for myself, and it’s kept me in touch with the field. For example the technical services department still reports directly to me, which is pretty unusual in our industry.

I meet with my direct reports every two weeks. I want our people to be entrepreneurial here, and that was a big transition I had to make. Coming from the smaller Canadian operation to a company this size, I had to let go and allow my managers to manage.

You can’t micromanage in this position, because no one can be an expert in all things. You’re only as good as the people around you.

Equipment can quickly become commoditized. What do you think sets STIHL apart? We’re very fortunate at this company, we have no bank loans and a lot of that is attributable to being a family-owned company. Mr. Stihl has said to me on a few occasions, “Fred, if I was just in this business for the money, I would’ve gone about it completely differently.” And the family reinvests a majority of the proceeds back into the company – land, equipment, machinery, technology. And fortunately for me, I don’t have to stand up every quarter in front of shareholders and talk a very short-term window of what just happened the last three months and what’s going to happen the next three months.

A short-term vision for our owners would maybe be a year and a half or two years. It’s been a real pleasure working for the Stihl family. I have sat in meetings to discuss some problems and we’re looking at possible solutions, and Mr. Stihl will say, “Well, of course we could address the issue and fix it this way, or we could address the issue and fix it that way. This would cost maybe a few more million dollars, but, of course, that’s the correct way to fix it, then that’s what we will do.”

That’s a very German approach, I think. It’s putting your money where your mouth is. It really is. Let’s not put a Band-Aid on it. Let’s do it right and let’s fix it. I’ve sat in meetings and thought, “That’s a lot of money.” But you think, “Well it’s a lot of money, but it’s the right thing to do.”

Tell me more about the transition from Canada to Virginia Beach. What did you bring here from that operation that’s served you well? First, STIHL Ltd. is a sales and distribution location, not manufacturing, so that side of the business, along with export, was somewhat different. Also, the Canadian operation is dealer-direct. There are no independent distributors or branches, so I was dealing directly with our customers, essentially one on one. The advantage to that is you’re very plugged-in to the market. Canada’s a huge country, but I got to know a lot of the dealers personally and their families, their kids and see them get married and that kind of thing. But I was the first employee of that company. I started it. I knew every detail. I knew how large the warehouses were, what kind of forklifts we had.

Probably what kind of pens you ordered for everyone. Exactly. And that kind of minutiae I had to let go of coming here.

Was that difficult? It was. It was. It probably took me about 18 months to realize I either had to quit drinking as much or get more sleep or something, because this wasn’t going to work if I tried to manage this at the same level. Of course, a lot of people knew me from my time in Virginia Beach before I went to Canada and others got to feel comfortable with me over time, and I got comfortable with them.

What’s your earliest memory of STIHL as a company? My father brought home a STIHL model S 10 chainsaw in the mid ’60s, and I had to go out on our property and cut firewood. He brought home this German chainsaw and said, “Go to it.”

How do you see your customers changing from a decade ago? Well, we attempt to segment the customers because of our product line. Traditionally, STIHL was thought of as the chainsaw company. But somewhere around the mid- to late 1980s, the market changed very dramatically with a sharp decline in the sale of chainsaws, for a variety of reasons. Frankly, the primary professional market for us now is the landscape market.

This is a prime target customer for us because if their machines aren’t working, they’re not making any money. Construction is another key component of our business because of our strength in the cut-off machine market. Much of their business is based on efficiency and time management, so service from their equipment provider is critical. If the landscaper walks in and says, “My blower or my trimmer isn’t working,” many STIHL dealers will say, “Well, here, take this one and yours will be ready on Monday.”

We have a very dominant position in the market, but you have to continually be looking at not only who your customer is now but who is your customer going to be in five years? Where are they located? What is their demographic in terms of their lifestyle, the average income? We spend a fair bit of time looking at that, and I think have done that reasonably successfully.

If you were able to get all the landscapers in the United States together and tell them one thing, what would you tell them? They have to be good stewards of the environment. People are far more sensitive in this generation to caring for the environment than in the past.

Continuing to pursue education and training for their workforces is essential. It’s become far more sophisticated in the last ten years, but there are some extremely professional companies that are very, very well run and there’s still people that have a two-man crew with the pickup that show up and don’t care where they blow the clippings and don’t care what time they may start in the morning. That doesn’t help the industry.

What can contractors expect from their equipment manufacturers in the next five years in terms of product development or support? Things like noise abatement and reduced emissions are certainly concerns for landscapers, and this is one of the reasons we’ve made a bit of a thrust into the battery-powered segment with our lithium-ion products for use around schools, hospitals, churches, universities. It’s a bit of a niche product right now, but I think as time goes on and battery technology continues to improve, this area will expand. The technology is being advanced by the automotive industry. Certainly, we will see more and more of it in the market for landscapers and other professional users like tree services, for example.

Environmental preferences of users, as well as their customers, coupled with new EPA regulations are driving more options. I think you will also see more propane products, as well as more electric products. Of course, new technologies for gasoline-powered equipment will also be in the mix. It’s very interesting that, with the thrust of batteries and electric, people forget that GE had an ElecTrak rider back in the ’70s. It didn’t ever catch on; but, again, history teaches us that sometimes what goes around comes around.

The average contractor has a legitimately difficult choice to make sometimes when it comes to purchasing. What would you say to a contractor who says, “Well, I need three trimmers, but I can’t afford three STIHL trimmers, and these other ones from X manufacturer fit in my budget.” You asked me about my father, earlier. Very early on in my STIHL career, he provided me with a sign that actually hung in my office here that said this: “Quality is like buying oats. If you want good, clean oats, you must pay a fair price. If you want the oats that have already been through the horse, well they are a little cheaper.” You get what you pay for.

Again, having spent almost 41 years in this business, there are reasons those products are cheaper. For example with chainsaws, the average purchaser doesn’t understand that their cheap model doesn’t have chrome on the chain, the muffler has been stamped and is not treated for rustproof protection, the oiler may be a baby-bottle type oiler rather than a gear-driven oiler and that instead of a proper air filter, the unit may have a piece of felt in place. That cheaper unit looks very similar and it will cut wood, but it won’t cut wood for very long.

That’s something that I joke about when I’m working a trade show when people come by and say to me, you know, “My grandfather had an 041 and my dad had an 028,” and you know, those are still running today. I look at them and say, “Do you ever think about buying a new one?” We appreciate the compliment, but we also appreciate your business if you consider buying a new product.

Will STIHL products ever be sold in mass-merchant retailers? No, no. We have no plans to do that, nor a compelling reason to do so. Our current distribution strategy has helped us achieve the success we enjoy today.

I’ll tell you a little background there, too. Peter Burton, our recently retired vice president of sales and marketing, and I – we would go to these dealer functions and, very late in the evening a dealer would look over and say, ‘Fred, you know, Fred. Come on, you can tell me. Honda did it to us and Husky has done it to us and Echo’s done it to us and one day, STIHL’s gonna have to sell the big boxes, right?’

You know these people reasonably well, but they were understandably suspicious. So Peter and I sat and noodled this over at some length, and we said, OK, we’re going to put it in print. We’re going to go national with a campaign that says, “Why is the world’s number-one selling brand of chainsaw not sold at Lowe’s or Home Depot?”

After you’ve done that, there’s no way back. You have drawn the line in the sand. That’s who we are. And I can tell you from knowing Mr. Stihl and his son, Nikolas Stihl, who took the reins as head of the advisory and supervisory board July 1 in Germany, they are all about the servicing dealer. That has really become one of our major distinctions in the go-to-market strategy, and it’s been very successful for us.

What would you say is your greatest accomplishment? One of the things that I take tremendous pride in is that in the over 30 years being president of both the Canadian and U.S. companies, I’ve never had to put someone out of a job for the lack of work.

Of all the tools that you make, which one is your favorite? Oh, I’m a chainsaw guy. That’s what I cut my teeth on. It’s not a macho thing; it’s just that I really enjoy chainsaws – I grew up with them. I still cut my own firewood.

Explore the October 2012 Issue

Check out more from this issue and find your next story to read.

Latest from Lawn & Landscape

- PERC helps debut propane direct-injection fuel system at ACT Expo 2025

- Retargeting Ads – A Secret Weapon for Growing Your Lawn Care Business

- Leading a growing company

- Project EverGreen launches Clean Air Calculator

- Rain Bird acquires smart lawn care company OtO from Toronto

- PBI-Gordon names Marvin as VP of research and development

- Mean Green rolls out Vanquish Autonomous mower

- Focal Pointe launches new podcast series