Even though the summer might have been tough on your bottom line, the winter doesn’t have to be. Consider expanding your deicing program to make sure you have whatever salt and ice melting blends you need for your business this winter.

Despite what you may have read about municipalities running short on salt during the last two winter seasons, supplies of deicing salt and ice melt blends should be sufficient for the upcoming winter if you make your commitment early and bring in “safety stock” as a contingency for a strong winter.

Here are some ice melt supply forecasting tips:

Be realistic in your estimates for products – out of the last 20 winter seasons, eight were above average, eight below and two were average.

Set up a contingency plan for extremes in either direction – either too much winter demand or too little.

Make room for extra space to stock bulk or package ice melters. Realize that if you take material in early you may have to carry some over next spring, but eliminate out-of-stocks if the winter weather gets out of hand.

Develop a good relationship with your ice melter supplier and let them know if you are flexible when the weather hits. Can you take deliveries after hours? On weekends? Do you have 24/7 phone contacts?

Make a commitment to a supplier and work with suppliers that have good supply-chain systems. These suppliers know what quantity of products they have available at any given time, they have planned for your winter demand, and they have allotted amply supply to customers who have committed to buy from them for the season.

According to Planalytics, the upcoming snow season in the U.S. is expected to be one influenced by both the transition to El Nino and the recent volcanic eruptions in the northern latitudes. El Nino, the warming of Pacific waters, portends a stronger southern storm track across the U.S. and has been responsible in prior years for significant snow and ice in the southern and eastern regions. In fact, this will be the strongest El Nino since 2002-2003 when East Coast cities received 150 to 200 percent of normal snowfall. Amplifying this potential are recent high latitude volcanic events, which typically produce a colder regime in the eastern half of the U.S.

The potential for increased snows will also exist in the Mountain West. While snow events across the northern tier and Midwest are expected to be robust, demand for ice melt is likely to lag record levels last year.

A salt and ice melter supplier with a strong weather service can also provide you with up-to-date forecasts of impending storms which may prompt you to order in advance to avoid the rush after the weather hits. Suppliers working with weather services also should be adjusting their production and storage plans to anticipate trends in geographic demand so they have products available in the right places at the right times when weather hits.

In deciding what products to put on your shopping list for the upcoming season, consider the weather in your area. What is most important in Kentucky may be the melting speed of ice and snow for less frequent storms, while a lower temperature melting point for ice and snow is more critical in Michigan where winter conditions are typically colder. Your supplier should be able to offer a range of fast-melting, economical and low-temperature-melting ice melt blends and salt.

In addition, more customers are concerned about the impact of ice melters on the environment and interested in ice melt blends on the market that are safer for plants, pets and surfaces compared to plain salt. Additives in the best blends may contain ingredients that serve to minimize the impact of ice melters on paved surfaces. The types of surfaces that appear to be the most susceptible to damage from ice melters are poorly sealed pavement or concrete, new concrete (less than 1 year old) or poor quality concrete. Conduct a pre-season audit of your clients’ paved surfaces and recommend properly sealing such pavement, in addition to using less harsh ice melters, as a way of protecting further damage to such surfaces.

The author is the marketing product manager for Morton Salt in Chicago.

Explore the October 2009 Issue

Check out more from this issue and find your next story to read.

Latest from Lawn & Landscape

- LawnPro Partners acquires Ohio's Meehan’s Lawn Service

- Landscape Workshop acquires 2 companies in Florida

- How to use ChatGPT to enhance daily operations

- NCNLA names Oskey as executive vice president

- Wise and willing

- Case provides Metallica's James Hetfield his specially designed CTL

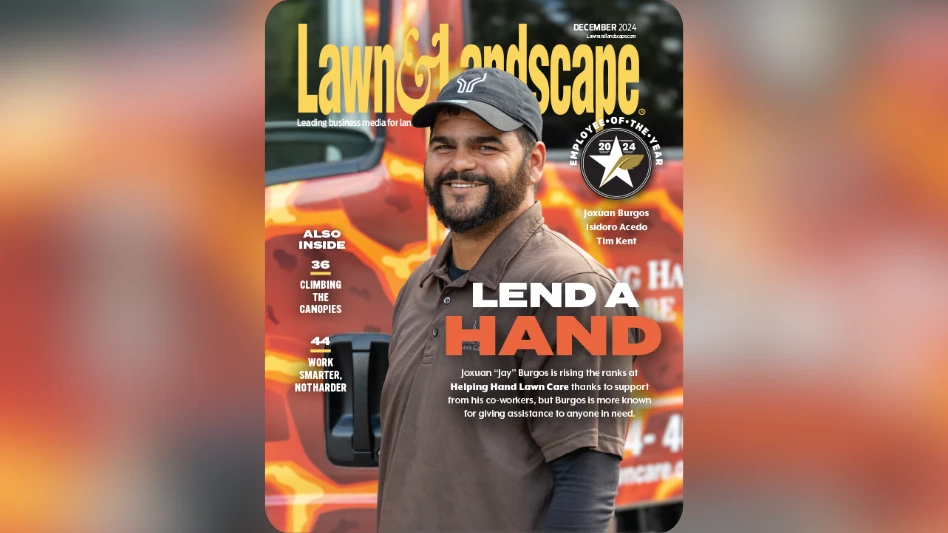

- Lend a hand

- What you missed this week