Wells CargoOpen or enclosed, custom or off-the-rack, trailers are integral to any green industry operation. Here’s how two companies approach buying.

Wells CargoOpen or enclosed, custom or off-the-rack, trailers are integral to any green industry operation. Here’s how two companies approach buying.

Tried and true

After working at another landscape company for years, Scott Anderson decided to head out on his own. He founded Vivid Scenery in Leesburg, Ind., and one of the first things he purchased was a new, custom trailer from Wells Cargo.

“The first thing I bought, other than a truck, was that enclosed trailer. I ordered that trailer right out of the chute and it was by far the best thing I ever did,” Anderson says. “For functionality and representing a company with an image, it was huge.”

And Anderson says he’s planning on buying two more trailers soon.

Anderson’s current trailer – a long, black model with dark red flowers and the Vivid logo emblazoned on the sides – gets used for most everything the company needs, but the bulk of the work is transporting plant material from suppliers to job sites. To avoid damage to the trees, Anderson had Wells Cargo bump up the ceiling to 6½ feet.

“The majority of it is definitely headroom,” he says. “By transporting plant material, we need some decent height in there. I wanted to do it this way because when we carry ornamental trees we want to be able to bring the material up and set it up straight, so we can put more material in there.”

He also added equipment racks inside, and bulked up the torsion axel strength and reinforced the real tailgate to handle the added weight of more trees. His supplier was two hours away, and he wanted to be sure the equipment could handle the strain. “Other trailers we would overload often, especially with plant material,” he says. “I know we’ve bent axels.”

And while the added height of the trailer adds headroom inside, it also adds display space outside. “We use our trailer a lot for advertising, so I plastered our logo all over the side of it,” he says. “Image is everything. If you’re traveling down the road with a moving billboard, it’s free advertising.”

Vivid, a full-service property management company, does mostly landscape and hardscape installations. The firm has 10 employees and pulls in about $1.5 million a year.

Signs of safety

Lilburn, Ga.-based Nature Scapes, does mostly lawn maintenance, employs 150 people in season and does $6-7 million a year. It runs 60 trucks and seven trailers of different designs: tandem-axel models for heavy equipment, vacuum trailers for leaf pickup and enclosed box trailers for floral work. The trailers also come from disparate manufacturers: Track Vac for leaves and Haul Mark for the box models. Now-defunct Mobile Trailer Manufacturing did the flatbeds.

Mike Cates, fleet manager, says he looks for safety when he’s buying. And he has a leg up: He spent almost 30 years running a large equipment rental operation in Atlanta.

“It’s just the way it’s made. If a person was out looking for a trailer, I think it’s a roll of the dice. They don’t really know what to look for,” he says.

“It’s just the way it’s made. If a person was out looking for a trailer, I think it’s a roll of the dice. They don’t really know what to look for,” he says.

He recommends contractors examine the trailer’s construction. “You look at the way they’re built – the welding they use, thickness of materials, what it’s made of in the first place,” he says.

He also urges contractors to examine a trailer’s vital systems. Look for enclosed wiring, sound tires and a weight raitng suited to your intended payload.

“It’s really dangerous out there on the interstate,” he says. “If they’ve got a John Deere backhoe on there and they’re hauling butt down 285 ... that trailer could disintegrate at any minute.”

The author is associate editor of Lawn & Landscape. Reach him at cbowen@gie.net.

Explore the October 2009 Issue

Check out more from this issue and find your next story to read.

Latest from Lawn & Landscape

- LawnPro Partners acquires Ohio's Meehan’s Lawn Service

- Landscape Workshop acquires 2 companies in Florida

- How to use ChatGPT to enhance daily operations

- NCNLA names Oskey as executive vice president

- Wise and willing

- Case provides Metallica's James Hetfield his specially designed CTL

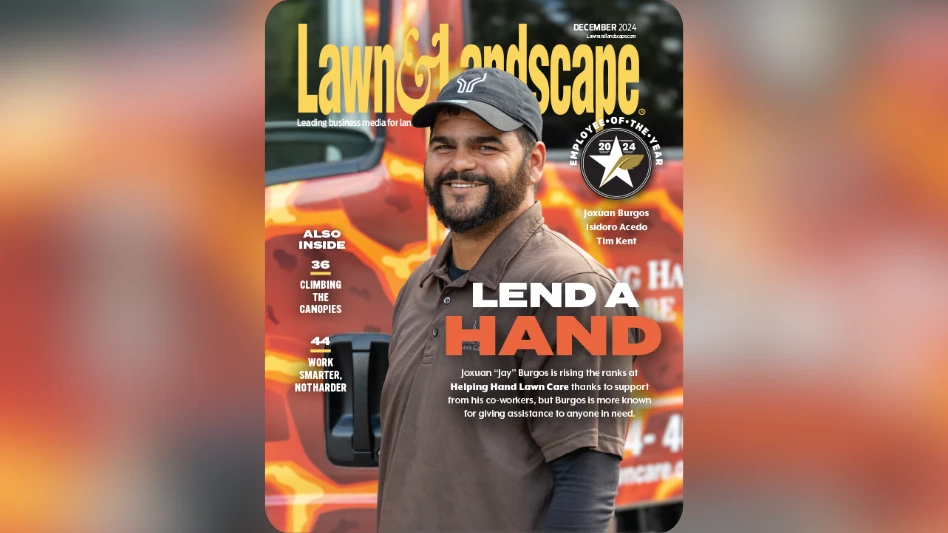

- Lend a hand

- What you missed this week