Contractors who invest in a skid steer are getting more than one piece of equipment – these are machines that wear many masks. With a variety of attachments available, skid steers have the ability to multi-task, turning one machine into an equipment fleet.

Whether used for large-scale excavating projects, moving loads or even as a landscape installation tool, skid steers have steadily grown in popularity over the last decade as more contractors invest in capital to meet various work needs. And the options for skid steers, including horsepower, size, operator controls and attachments, allow contractors to personalize machinery depending on their job requirements.

CONSIDERING CRITERIA. Because Skid Steers are available in a wide range of sizes and operating capacities, a contractor might feel as if he or she is customizing the machine for their job intentions. And, in a sense, this is true. However, before purchasing a machine that will work efficiently for the company, a contractor must evaluate what purpose the skid steer will serve.

The condition of the job site and the primary application of the machine are important considerations to evaluate before determining what options the skid steer should include, explained Tom Banner, associate marketing manager, Case Corp., Racine, Wis.

"Is the contractor working in confined areas where a large unit would not fit or would be limited by a lack of maneuverability? Or will load and carry be his primary application?" he inquired. "Is the contractor loading into high trucks and hoppers where dump reach and dump height are critical? What type of surfaces will he be working on?"

All of these questions are key when making a skid steer purchase, Banner added, because there is not one particular skid steer that is perfect for every contractor or that will handle every application. Assessing the uses for the machine is critical before a contractor can determine the amount of horsepower needed and attachments to purchase.

"People need to look at their standard work areas, their jobs and then size the machine to fit their needs," said Monte Mowry, product manager for Mustang, Owatonna, Minn. "Contractors who normally do small residential landscape work may not need the larger, bulkier machines."

Along with catering the machine to job requirements, contractors should also consider operator comfort. For an operator spending hours in a skid steer on a work site, the atmosphere of the cab can influence productivity. The position of the controls, seat and whether or not the cab is covered are features that affect the ease of operation for technicians.

"If contractors are running up to seven hours a day, they don’t want something uncomfortable," noted Lynn Roesler, skid-steer loader product manager, Melroe Bobcat, Fargo, N.D. "A suspension seat will smooth out bumps and can take the shock load out of an operator‘s back, and enclosed cabs can be heated or cooled."

Visibility and location of controls are also important, he added, describing calling a contractor’s options ‘The Burger King approach.’ "Having it your way," whether that means feet controls or hands controls, is one way to customize the skid steer for the operator’s needs. Hands-only operation might be easiest for newer operators, while the hand/foot combination is probably most popular because this option has been available for the longest.

Serviceability is another contractor convenience that is wise to consider when purchasing a skid-steer loader, including the accessibility of covers and doors for oil and filter changes and availability of customer service representatives to address machine problems. This is one area that Tamotsu Yamamoto, a mechanic at Del Conte’s Landscaping, Fremont, Cal., said can be frustrating.

"We do our own repairs, but right now we have issues with frames tearing out and we can’t contact our representative," he commented, stressing the importance of investing in regular machine maintenance.

Finally, safety features are an essential feature on all skid-steers. Besides urging operators to exercise common sense, Mowry advised safety lock-out systems that are easy to use so technicians take advantage of them.

PACKING POWER. Regarding productive machinery, some will say that more power means more work. However, whether or not the machine is efficient depends on if the power and size of the machine are appropriate for the job requirements, Banner explained.

Strength can be measured in several ways – horsepower, operating capacity, operating weight or breakout force – and the operator must determine which is most important for their application. Just as a machine that is lacking horsepower will slow down a large-scale excavating job, a machine with too much horsepower that is transporting cottonseed is wasting energy.

"Typically, a contractor should utilize the most powerful machine that will not exceed the physical size that the job or hauling equipment will support," Banner said, referring to this measure as ‘power density.’ "That’s what a skid steer is all about – a powerful and versatile machine that can perform effectively with high maneuverability."

Roesler also noted that horsepower, alone, is where some buyers can miss the mark when choosing a machine that will meet their needs and perform efficiently. Higher numbers don’t necessarily mean higher productivity, and since horsepower is what raises prices, contractors should be realistic when making this decision.

"Contractors should care if a model has 100 horsepower or 70 horsepower so long as the model they buy will do the job they need it for," he added. "Where you’ll mainly notice horsepower making a difference is in heavy excavating. If a machine were short of horsepower, you would notice that it would not be able to load the bucket as quickly."

Skid steers are purchased most commonly with 50-horsepower engines, observed Kelly Moore, product manager of skid-steer loaders for Gehl Co., West Bend, Wis. And though coordinating power output with workload is necessary, packing more horsepower also generally increases hydraulic power to operate attachments. More hydraulic power means more productivity.

Yamamoto considers hydraulic pressure a more significant consideration than the moving speed of the machine when it comes to horsepower.

"We have the high-flow attachments on our skid steers, which affects the hydraulic pressure," he explained. "I don’t believe the horsepower for moving the machine around is as much of an issue as the horsepower of the attachment."

Instead of purchasing a machine with more horsepower, Yamamoto suggested installing an extra pump on the skid steer to increase the hydraulic pressure. This allows the machine to run the same engine while giving the hydraulic system a boost to handle powerful attachments.

ATTACHED BENEFITS. Skid steers are known for their versatility – their ability to complete the tasks of many dedicated machines. Attachments are what make this possible. Palate forks, backhoes, earth augers, brooms and landscape rakes name just a few of the myriad tools available for use on skid-steer loaders.

"There are easily 75 to 100 different widgets," Mowry noted, adding that a generous attachment collection can be pricier than the machine itself.

When purchasing attachments for a skid steer, a key consideration is compatibility, he added. The hydraulic flow of the attachment must be compatible to the flow of the machine, and the hook-ups must also correspond. A two-pin style hook-up is a universal style that will allow contractors to take advantage of the versatility of the machine because most attachments are designed with this standard. However, a contractor should be in tune to these variables when thinking about adding attachments, Mowry stressed.

Banner compares attachment shopping to buying a computer.

"You can choose the attachment that will best suit your application and then match that attachment to the skid steer that can best handle the attachment," he explained. "This is very much like buying a computer when you first determine what software you need, and then you select the computer that will run the best software."

High flow attachments are a special consideration for contractors, Banner added, because they cannot be field installed on all skid steers.

Once contractors realize the flexibility attachments provide, they often purchase more. "Most of the time they’ll purchase one or two attachments to begin with, but as they see what the machines will do, they add more," he observed. "A lot of attachments can be used on the next machine they buy."

Roesler said some customers take attachment flexibility into their own hands and brainstorm tools to handle construction situations they deal with on a regular basis.

"Customers that own skid-steer loaders get ideas for new skid-steer attachments," he added. "They find a better way and they develop an attachment."

The lure of multiple attachments and compact machinery is what leads some to the newer compact utility vehicles, known for their ability to maneuver in tight places where some conventional skid steers cannot fit. They can move through a three-foot gate, Roesler commented, describing the machines as "tool carriers – a mobile power unit for running attachments." Because of their strong hydraulic horsepower, they trade tools easily and offer contractors an abundance of attachment options.

"But if a contractor is doing a lot of excavating, backfilling or bucket work, a skid steer will do a better job," he noted.

DOLLARS THAT MAKE SENSE. Despite the various functions skid steers serve for contractors, a skid-steer loader can take a bite out of a business budget. But most companies who invest in the machine say the value justifies the price. Adding a skid-steer loader with a couple of attachments to their machinery fleet narrows the need for several dedicated machines that are retired to the garage after completing an individual task.

"When contractors pencil out the purchase of the machine or renting it with monthly payments, the productivity of the machine, what it will do for them and the multiple uses they can get out of a skid steer loader, they’ll find the run on the investment is very, very good," Moore commented. "Contractors using the machines correctly will find that the utilization of skid-steers is very strong."

And, compared to purchasing a dedicated sweeper, for example, that might cost $20,000, a contractor can purchase a skid steer for a comparable price, add maybe $10,000 in attachments and replace the work of five dedicated machines, Roesler pointed out.

"The key is that you can keep a skid steer busy all the time," he described. "The bang for the buck is extremely good."

"A prime example is a trencher," Mowry added. "Some models have a backhoe and others don’t. The skid-steer can power a backhoe and a trencher and still be used to do other things. Once the trencher is done doing the trench, you shut it off because it can’t do anything else."

This ability to multitask is what keeps the skid-steer market growing today and has for the last decade. Moore predicts more businesses investing in the second, third or 10th skid steers in their fleets after having reaped the productivity and efficiency that these machines offer. Many contractors are choosing to replace tractors with skid steers, and the variety of attachments creates even more of a draw to the machine, he said.

"Construction equipment gets work done faster, easier and more efficiently," Banner explained. "The right piece of equipment will make the contractor money. If it doesn’t, then he shouldn’t have the equipment."

Banner sees the attempt to control the growing expenses of employee compensation as a challenge contractors will have to address in this new century, and more productive equipment might be one way to curb this trend, he said.

"One way to do this at the job site is to use more productive equipment that can do more work," he suggested. "Another way is to get maximum utilization out of the equipment."

And those who cannot afford to make this "productive equipment" a permanent part of their machinery fleet can turn to a growing skid steer rental market. Contractors can lease a skid steer or simply a few attachments, for those who have a specific work need that requires a tool they do not own or do not want to invest in.

Banner said one of the driving forces behind the rental market today is the fact that the machines are more available.

"Ten to 20 years ago, finding a rental center that rented a skid steer or loader was rare," he noted. "Today, finding one that doesn’t is even more rare. As the availability for rental units increases, contractors will increasingly rely on rental units vs. owning their own equipment, particularly for those units that are not primary machines."

As the market continues to flourish, so will the demand for skid steers, Roesler noted. Skid steers are a piece of equipment contractors have gravitated towards using, he said, and as long as the growing economy pushes more homeowners to invest in their property, contractors will want to invest in skid steers. Their flexibility makes the machinery a wise investment, he added.

"That’s been a hallmark of skid steer loaders – flexibility," he stated. "You get better utilization from the loader, which is a better investment."

The author is a Contributing Editor to Lawn & Landscape magazine.

Explore the February 2000 Issue

Check out more from this issue and find your next story to read.

Latest from Lawn & Landscape

- Our Holiday Lighting Contest rolls on

- LawnPro Partners acquires Ohio's Meehan’s Lawn Service

- Landscape Workshop acquires 2 companies in Florida

- How to use ChatGPT to enhance daily operations

- NCNLA names Oskey as executive vice president

- Wise and willing

- Case provides Metallica's James Hetfield his specially designed CTL

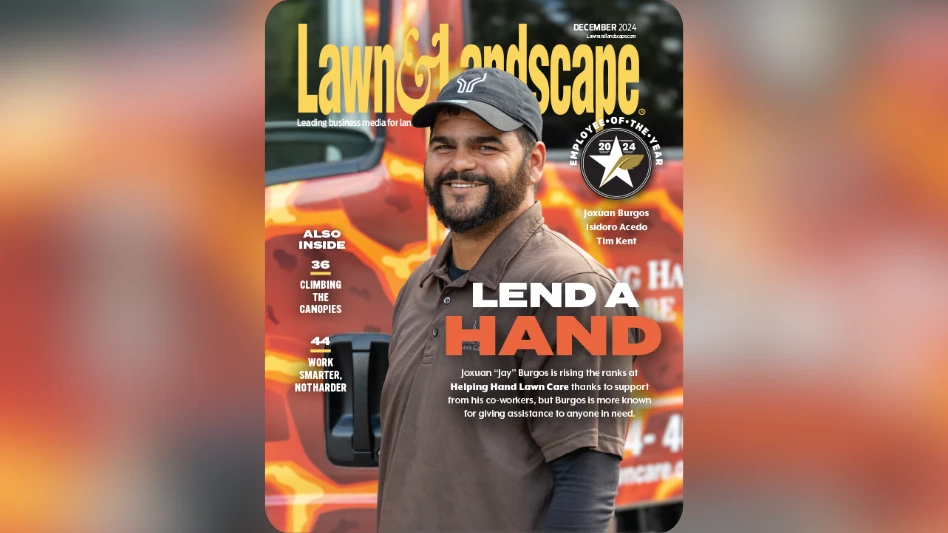

- Lend a hand