When Anthony Bulfamante’s company, A Bulfamante Landscaping, was awarded a very large tree planting contract in 2000, in Manhattan, New York, he knew he’d have to approach it differently than previous jobs.

The idea of excavating a tree pit by hand and then using a skid-steer to plant trees in a tight area was not going to be the most efficient method.

So he purchased a tractor loader backhoe, and the job went a lot smoother than it would have if he stuck with the approach he used on smaller jobs.

“We were able to do the entire project with one machine and can drive it from location to location instead of being forced to put it on the trailer,” says the owner of the company, which serves Westchester County in New York City and Fairfield County in Connecticut.

In the beginning.

Bulfamante first owned a JCB 212 tractor loader backhoe, and then a couple of years later bought a larger size.While he never rented before buying, Bulfamante did his homework before purchasing his first backhoes. He asks a dealer for a reference of someone who has purchased a piece of equipment so he can ask a user questions about it.

“Actually speak to someone who actually owns and uses the equipment – not always going off the dealer’s advice,” he says. “Speak to a contractor who’s had experience with the actual equipment.”

Instead of saving money upfront by buying used equipment or renting, Bulfamante opts to buy new equipment. Though it is a perk because the company is in the position to make those kinds of capital investments, he says the math shows it’s better to buy new if you can.

“I keep my fleet current,” he says. “The benefit to that is before the machine starts needing costly repairs, that same money will pay down a new machine that has no problems.”

Easy operation.

One feature Bulfamante recommends buying on a backhoe is a side-shift option. On a traditional loader backhoe, the boom sticks out of the back and it requires a large amount of space, he says.“So, it can be comparable to a wheeler loader or skid-steer, but also has the flexibility to have a backhoe attached to the same machine,” he says. “I’m a city contractor, so we don’t have a lot of room on our sites, so you have to get a lot of machine in a very compact footprint.”

Sponsored Content

Lawn and Landscape Marketing on a Budget

Digital marketing can feel overwhelming when you’re working with a limited budget. Websites, SEO, social media, and paid ads can quickly add up, but you don’t need to do everything to see results. By focusing on cost-effective strategies, you can still make a big impact without overspending.

Sponsored Content

Lawn and Landscape Marketing on a Budget

Digital marketing can feel overwhelming when you’re working with a limited budget. Websites, SEO, social media, and paid ads can quickly add up, but you don’t need to do everything to see results. By focusing on cost-effective strategies, you can still make a big impact without overspending.

Sponsored Content

Lawn and Landscape Marketing on a Budget

Digital marketing can feel overwhelming when you’re working with a limited budget. Websites, SEO, social media, and paid ads can quickly add up, but you don’t need to do everything to see results. By focusing on cost-effective strategies, you can still make a big impact without overspending.

Sponsored Content

Lawn and Landscape Marketing on a Budget

Digital marketing can feel overwhelming when you’re working with a limited budget. Websites, SEO, social media, and paid ads can quickly add up, but you don’t need to do everything to see results. By focusing on cost-effective strategies, you can still make a big impact without overspending.

Sponsored Content

Lawn and Landscape Marketing on a Budget

Digital marketing can feel overwhelming when you’re working with a limited budget. Websites, SEO, social media, and paid ads can quickly add up, but you don’t need to do everything to see results. By focusing on cost-effective strategies, you can still make a big impact without overspending.

Sponsored Content

Lawn and Landscape Marketing on a Budget

Digital marketing can feel overwhelming when you’re working with a limited budget. Websites, SEO, social media, and paid ads can quickly add up, but you don’t need to do everything to see results. By focusing on cost-effective strategies, you can still make a big impact without overspending.

Sponsored Content

Lawn and Landscape Marketing on a Budget

Digital marketing can feel overwhelming when you’re working with a limited budget. Websites, SEO, social media, and paid ads can quickly add up, but you don’t need to do everything to see results. By focusing on cost-effective strategies, you can still make a big impact without overspending.

Of his 28 employees, 10 are capable of operating his backhoes. He says training on the machines combines mini-excavator and skid-steer training and is conducted at a nearby farm.

“We don’t just give the guy the keys on a job in the middle of Manhattan and tell them to operate a piece of equipment,” he says.

Bulfamante says he likes to spread the hours out on his equipment and puts 200 to 300 hours on his backhoes a year. He’ll hang on to a machine for seven to eight years before he decides to sell it or trade in.

“In my experience,” he says, “keeping it fresh and new, they really don’t break down.”

L&LGet curated news on YOUR industry.

Enter your email to receive our newsletters.

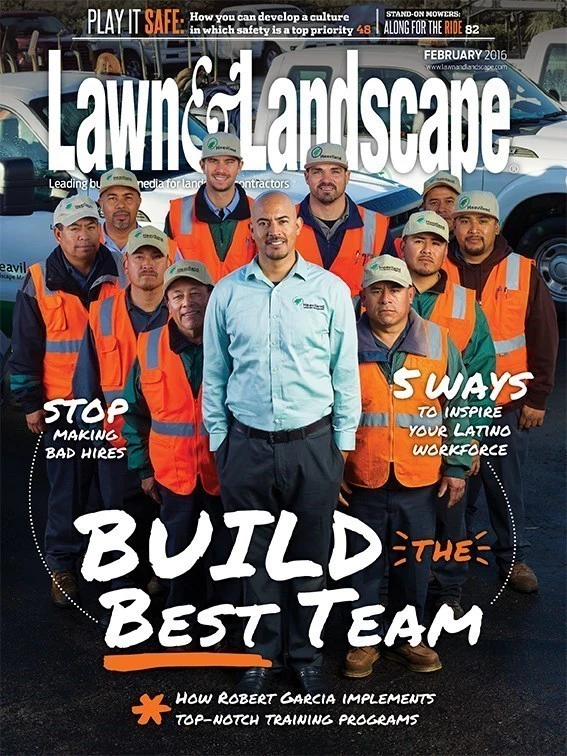

Explore the February 2016 Issue

Check out more from this issue and find your next story to read.

Latest from Lawn & Landscape

- Project EverGreen helps revitalize Milan Park in Detroit

- Trex Company wins Product of the Year, Judges’ Choice Winner at Environment+Energy Leader Awards

- General Equipment & Supplies in Fargo adds Takeuchi equipment

- Mariani Premier Group acquires Hazeltine Nurseries

- EnP Investments adds Mark McCarel as Northeast territory sales manager

- Our April issue is now live

- Ready or not

- Tribute to an industry guru