Your budget can help you determine everything from whether or not your foreman can have that raise he asked for to how much to charge for a new job to when it’s time to upgrade your equipment.

Mike Lysecki, chief technical officer of LMN, shared tips, tricks and ways to make an accurate budget for a better bottom line on Tuesday. We sat in on the first of a two-day LMN training session, sponsored by Caterpillar, in Cleveland to learn what you should be thinking about when making your budget this year.

Don’t pay your workers a low wage. “It’s costing a ton of money because your staff isn’t making good decisions,” he said. “But when you’re looking at your budget, you want to spend as little on staff as possible. That’s not always your best move.”

Do attract talent by having a good reputation and company culture, and train staff well. The more efficient your people are at getting jobs done, the more time they can spend making more money. For example, spending a little bit more on wages for a good foreman is worth it since he’ll help get jobs done faster, and be able to take on more work, Lysecki said.

Don’t guess on estimates, and if you have guessed in the past, don’t rely on old numbers.

Do have consistent estimations with accurate pricing and a trainable system.

Don’t be unorganized about job plans or relay out of date information on the status. If crews don’t have timely updates on metrics, they don’t know how they’re doing on a project.

Do have a job plan that answers the who, what, where, when and why of the project. Use a scoreboard to see how efficient your crews are. This will also help you recognize achievers and identify underachievers.

Don’t estimate by unit price. If you’re assigning cost just by labor, rather than the price of material, you’ll end up bidding too high on easy jobs, and too low on hard jobs.

Do think of overhead costs as those that aren’t recovered in job estimates. Costs that can be recovered in estimates are job costs. For example, you wouldn’t including marketing costs in your job estimations.

Setting crew goals.

Field labor ratios are not only useful for determining how efficient your crews are, they can also tell you when you can afford to hire another employee, and help you explain what your crews need to do to get a raise.

Your field labor ratio is the percentage of your budget allocated to field labor. If that number is too high, either you aren’t being efficient or you need to take on more work. By calculating this number you can also determine how much more revenue you need to bring in to justify an employee’s salary.

If your foreman wants a raise, explain to them their crew will have to do enough work to keep that field labor percent the same. Just take the crew’s combined wages for the year, divide it by your field labor rate, and that will be the goal the crew needs to meet in order to get a raise.

According to LMN, the industry average is just over 24 percent.

Getting more efficient.

By looking at how long your crews are taking to do each task, you can see how much money you’re losing to down time and whether or not new equipment could be the answer.

For example, if you’re thinking of buying a covered trailer, look at how much time employees are spending loading and unloading a trailer and multiply by their wages. If a covered trailer is cheaper than the wages you’re losing, it could be a good investment.

The same is true with heavy equipment. Price out how much faster your crews could do a job with a larger piece of machinery. If it makes sense, you’ll be able to keep your profit margin without having to pass the price of the machine onto the customer.

Since jobs are going faster, crews can move on to other projects and make more money. “It’s a lot easier to buy equipment than it is to find more manpower,” Lysecki said. “The hardest thing to find and train and keep is people”

If you’re thinking of doubling up on equipment so that each crew has its own, look at the cost of sharing equipment. Think about the time it’s taking for someone to drive the equipment from the shop to Job A, the time spent on conversation, the transfer from Job A to Job B, the unloading and then the return.

“Even if they’re just stopping for 15 minutes to talk, with four guys, that’s an hour right there,” Lysecki said.

Latest from Lawn & Landscape

- LawnPro Partners acquires Ohio's Meehan’s Lawn Service

- Landscape Workshop acquires 2 companies in Florida

- How to use ChatGPT to enhance daily operations

- NCNLA names Oskey as executive vice president

- Wise and willing

- Case provides Metallica's James Hetfield his specially designed CTL

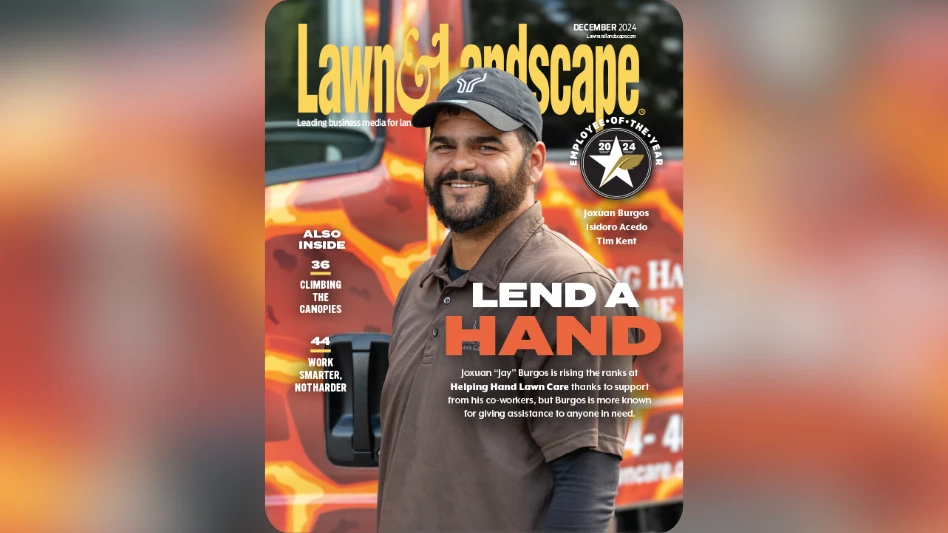

- Lend a hand

- What you missed this week