Winter means time to work on contract renewals or possibly servicing snow and ice removal clients. It’s also the prime opportunity to repair and prepare equipment for the upcoming year.

Taking the time during the off-season to make sure equipment is ready to roll in spring is key for lawn care operators like Tom Uncapher of Uncapher Landscaping in Columbus, Ohio.

As leaf cleanups finish, Uncapher brings all of his machines into his garage to have them washed and starts a thorough check of all of the parts. As the head of a crew of six employees, he works on routine maintenance alongside one employee he has trained personally as the team’s mechanic. “We go right into changing the oil and fuel filters and all the easy things right away,” he says. “Then, it depends on what kind of snow season we have for when I can buy the larger things that need repaired.”

Uncapher will rinse any dirt or grass out of backpack sprayers and make sure there are no leaks. In the fall, he’ll rinse them out and make sure no water is left in the tanks so they don’t freeze and crack. “In the winter, we'll check for crack seals/lines and replace as needed,” he says. “We'll order some spare parts also.”

Brian Lemmermann of Somerset Landscape operates across four states and keeps his three in-house mechanics on staff all year to maintain equipment before it can cause problems in the spring. During the winter, his mechanics start with the company’s trailers, repairing and repainting before moving on to other equipment.

Winter is also the time when Lemmermann’s team starts replacing older equipment, especially if it’s seen heavy use. The machines might not be in bad repair, but have hit a stage where he doesn’t want his crew relying on it every day in the field.

Help and communication. Uncapher teams up with his in-house mechanic when it gets hectic during the work season to keep his crew from waiting on repairs. He’ll send the machine out to the dealer for repair if the problem is beyond his own expertise, or if he just doesn’t have the time to handle it.

“If it’s in April or May, I’ll just tell them automatically, ‘I don’t have time to fix it. Take it to the shop,’” Uncapher says.

Occasionally, when breakdowns take out his spare equipment, he lets clients know about the slowdown. If he’s able, he’ll reach out to nearby LCOs to borrow a piece of equipment for the day to pick up the slack.

“Keep your avenues open to others, even your competition,” Uncapher says.

Though he does almost all his repairs in-house, Lemmermann maintains a tight relationship with his dealers, to make certain he can get service or parts when he needs them. “We don’t buy a machine unless the dealer stocks all the parts for it,” he says.

Before Uncapher’s crews return for the day, they clean and check the equipment for parts that need attention, he says. He’ll repair what he can in the evening, getting the morning crews off quickly after running down a checklist to make sure the team has the right equipment.

Lemmermann emphasizes the need to clean and take care of small maintenance issues as quickly as possible in the evening after coming in from the field to prevent future slowdowns.

“If your machine breaks down in the middle of the day, it’s a whole lot worse than taking the time to do the routine stuff at the end of the day,” he says.

The author is a freelance writer based in Ohio.

Latest from Lawn & Landscape

- LawnPro Partners acquires Ohio's Meehan’s Lawn Service

- Landscape Workshop acquires 2 companies in Florida

- How to use ChatGPT to enhance daily operations

- NCNLA names Oskey as executive vice president

- Wise and willing

- Case provides Metallica's James Hetfield his specially designed CTL

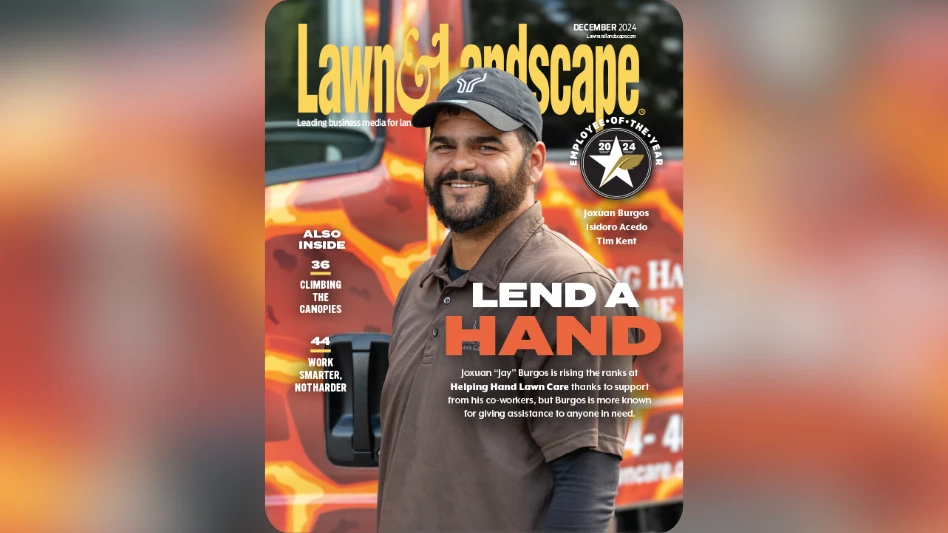

- Lend a hand

- What you missed this week